The Working Principle and Function of the Backwater Valve

Ⅰ. The function of the backwater valve

The function of the backwater valve is to adjust the return flow. Adjust the amount of branch circulation. If the amount is small, increase the opening, and if the amount is large, decrease the opening. The return water shut-off valve is installed at the return water end of the radiator to adjust the pressure difference between the inlet water and the return water, ensure the low noise operation of the radiator and realize the hydraulic balance at the end, and adjust the resistance balance of each heating loop.

The return water shut-off valve is installed at the return water end of the radiator to adjust the pressure difference between the inlet water and the return water, ensure the low noise operation of the radiator and realize the hydraulic balance at the end, and adjust the resistance balance of each heating loop. The product has a corresponding mark for the flow that other manufacturers do not have.

In some facilities that use hot water, the valve needs to be opened or closed after the water reaches a certain temperature. For example, in a solar hot water system, when the temperature of the water in the solar collector reaches 60 °C, the copper backflow valve is only Turn on to store hot water in the tank, and close the valve if it is below 60°C.

This kind of control method is generally realized by electronic control method at present, which requires high cost and inconvenient installation, such as power supply, temperature control instrument and solenoid valve.

Ⅱ. The working principle of the backwater valve (fill valve):

1. The automatic water replenishment valve is equipped with a decompression and stabilizer device. The pressure value can be adjusted with the pressure gauge and automatically maintains the adjusted system pressure; when the system pressure decreases, it automatically opens the water injection and automatically closes when it reaches the set pressure to avoid water pressure. Excessive damage to system equipment.

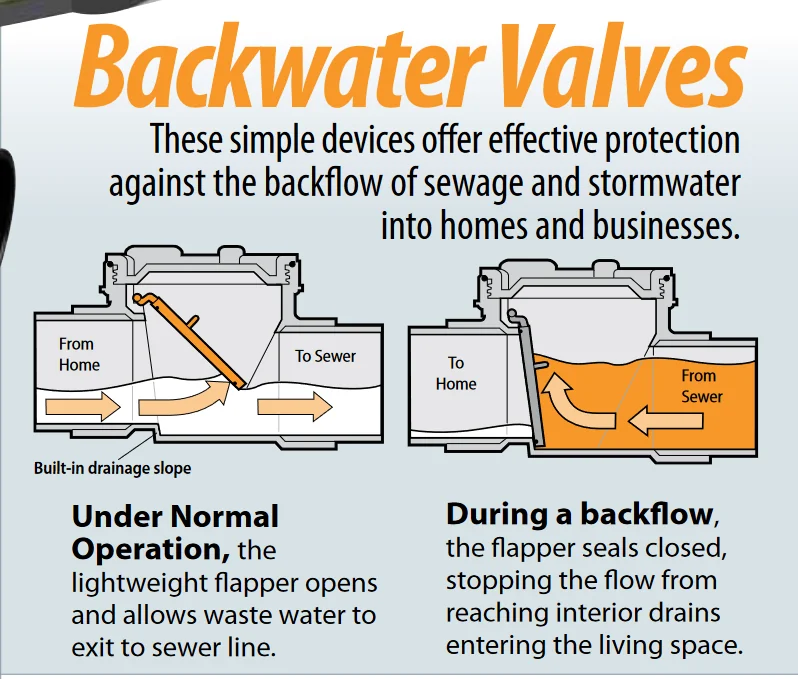

2. Prevent the backflow of system water; the automatic water replenishment valve has a check valve to prevent the backflow of system water when the water supply pressure decreases or stops.

3. Manual cut-off; in order to facilitate the maintenance of system equipment, the automatic water backwater valve (supplementary valve) is equipped with a manual cut-off valve, which can close the water supply for replenishment.

Carbo Bronze started in 1998 as a bronze ball valve supplier and valve fittings manufacturer and has become a leading company in the industry with a strong reputation in the US and European markets. We designed and built a brand new automatic casting line, introducing various technical talents and advanced management personnel. Our quality management system has passed ISO 9001/2008 certification, and our products are certified by CSA, cUPC, NSF, UL, etc. All materials are tested by the laboratory, and the test report is kept for three years for traceability. Welcome to consult.

Different Carbo Valves For Sale