Brass ball valves vs stainless steel ball valve, which is better?

Ball valves are widely used in various industries and applications for their reliable shut-off capabilities. When it comes to choosing the right ball valve, two popular options are brass ball valves and stainless steel ball valves. In this article, we will explore the characteristics, applications, and the pros and cons of each type, ultimately helping you determine which OEM ball valve is better suited for your specific needs.

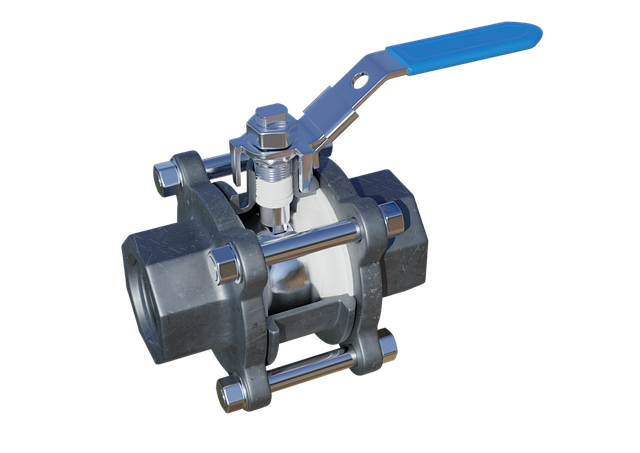

What Are Stainless Steel Ball Valves?

Stainless steel ball valves are made from high-quality stainless steel, which offers excellent corrosion resistance and durability. These valves consist of a hollow ball with a bore that rotates within a valve body, controlling the flow of fluids or gases. Stainless steel ball valves are known for their strength, resistance to high temperatures, and resistance to chemical and environmental factors. These valves are commonly used in industries such as oil and gas, chemical processing, pharmaceuticals, and water treatment.

What Are Brass Ball Valves?

Brass ball valves, on the other hand, are made from brass, an alloy of copper and zinc. Brass offers good strength, is easy to manufacture, and has excellent thermal conductivity. Brass ball valves typically consist of a ball with a hole in the center that rotates within a valve body, controlling the flow of liquids or gases. They are often used in residential and commercial applications, such as plumbing, HVAC systems, and general-purpose applications where the operating conditions are not as demanding as in industrial settings.

Applications for Stainless Steel Ball Valves

Stainless steel ball valves are preferred in applications where durability, corrosion resistance, and high temperatures are crucial factors. Some common applications include:

Oil and gas industry: Stainless steel ball valves are suitable for handling corrosive fluids and gases, making them ideal for offshore and onshore drilling operations, refineries, and pipelines.

Chemical processing: These valves can withstand exposure to various chemicals, acids, and alkalis, making them suitable for use in chemical plants, pharmaceutical manufacturing, and laboratories.

Water treatment: Stainless steel ball valves are used in water treatment plants, desalination facilities, and wastewater management due to their corrosion resistance and hygienic properties.

Food and beverage industry: The non-reactive nature of stainless steel makes it an excellent choice for applications in food processing, breweries, and dairies.

Applications for Brass Ball Valves

Brass ball valves are commonly used in applications that require moderate operating conditions and where cost-effectiveness is a consideration. Some common applications include:

Plumbing: Brass ball valves are widely used in residential and commercial plumbing systems for controlling the flow of water.

HVAC systems: These valves are used for regulating the flow of liquids or gases in heating, ventilation, and air conditioning systems.

General-purpose applications: Brass ball valves are suitable for a wide range of industries and applications where the operating conditions are not as demanding as in heavy industrial settings.

Brass Ball Valves vs. Stainless Steel Ball Valves: Which is Better?

Determining which type of ball valve is better depends on the specific requirements of your application. Here are some key factors to consider:

Corrosion resistance: Stainless steel ball valves offer superior corrosion resistance compared to brass ball valves. They are suitable for harsh environments and corrosive fluids.

Strength and durability: Stainless steel ball valves are generally stronger and more durable than brass ball valves, making them better suited for high-pressure and high-temperature applications.

Cost-effectiveness: Brass ball valves are often more cost-effective compared to stainless steel ball valves, especially for applications where extreme conditions are not a concern.

Environmental factors: Stainless steel ball valves are better suited for outdoor applications where exposure to elements such as saltwater or extreme temperatures is a consideration.

Industry standards: Some industries, such as oil and gas or chemical processing, have specific requirements for materials and standards. It is important to ensure that the chosen valve meets these industry standards.

In summary, both brass ball valves and stainless steel ball valves have their own advantages and applications. Stainless steel ball valves excel in demanding industrial environments that require corrosion resistance and durability, while brass ball valves are cost-effective solutions for general-purpose applications. Assessing the specific needs of your application, considering factors like corrosive environments, operating conditions, and industry standards will help you make an informed decision on which type of ball valve is better suited for your requirements.

Carbo is a leading brass ball valve factory in China. If you have any need, feel free to contact us.

Different Carbo Valves For Sale